High Quality Plastic Molded Parts 3D Printing Plastic Molds Product Service

Basic Info.

| Model NO. | PPL-M0100036 |

| Mould Cavity | Single or Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner& Cold Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Year |

| Multi Injection | Single/Double/Multi Color |

| Surface Requirement | Texture/ EDM /Spi Chrome Coating |

| Standard Delivery | 30 Days or 4weeks |

| Cooling | Baffles/Sprin Piple/3D Printing Water Line |

| Quality Assurance | Design Control, Steel Hardness Inspection Report |

| Production Material | ABS, PP, PC, POM, PMMA, Nylon, TPE, TPU etc |

| Tolerance Request | up to (±0.005mm) |

| Part Size Range | up to 2000mm |

| Color | Many Colors Are Avaliable |

| Style | Many Styles Are Avaliable |

| Transport Package | Carton |

| Specification | Custom |

| Trademark | Custom |

| Origin | Xiamen, China |

| HS Code | 8480710090 |

| Production Capacity | 35sets/Month |

Packaging & Delivery

Package Size 65.00cm * 55.00cm * 50.00cm Package Gross Weight 350.000kgProduct Description

High Quality Plastic Molded Parts 3D Printing Plastic Molds Product ServiceAdvantages:1. Free design and free sample.2. Sign NDA.3. ISO Certificated with the strict quality control system.4. 13 Years OEM&ODM Mould-making,metal and plastic processing experience.5. Good at spoken english and phone call communication.6.One stop solution and drop shipment for online sellers.Product Description

Product Description | ODM plastic injection molding |

Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

Standard: | ISO9001:2008 |

Quality: | RoSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your 2D, 3D Drawing |

Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

Mold Building Lead Time: | T1, 15-25 Working days, Part measurement report (upon required). |

Export Country: | All countries are reachable. |

Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

Mould Base: | Hasco Standard, European Standard, World Standard |

Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

Surface Finish: | Texture(MT standard), High gloss polishing |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Services

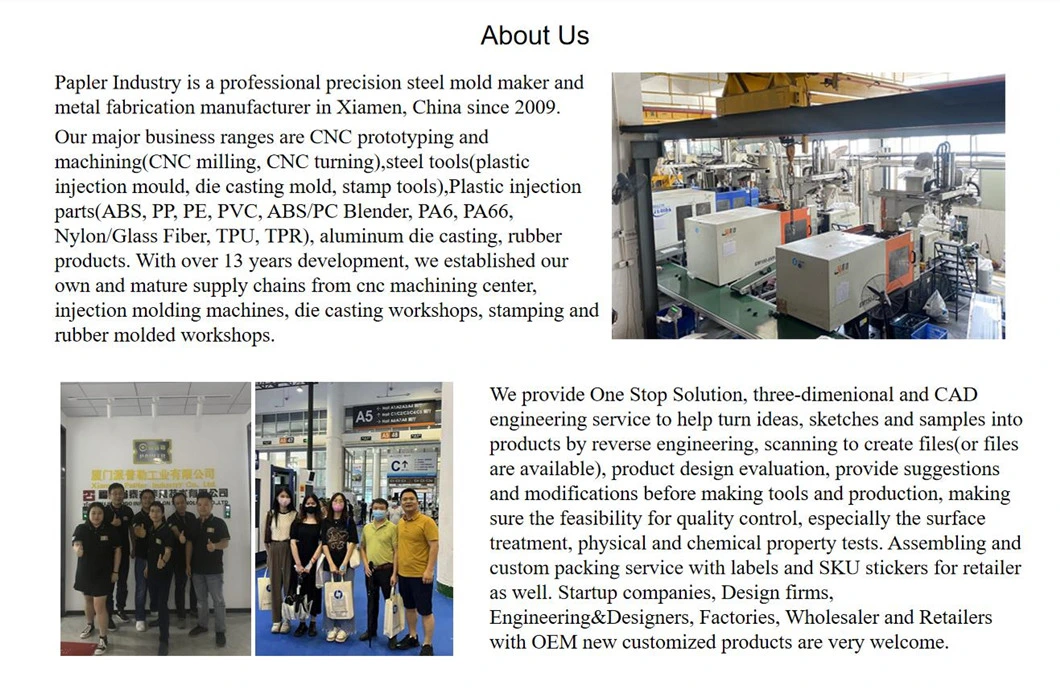

Papler Industry provides service of prototype making, mold design, mold production, mass production and assembly service in house. Our experience range from simple design to challenging technical parts.Company Profile

Workshops and Equipments

Cooperating Customers Our Word of Mouth Marketing

The best thing ever is the trust and win-win solution given by our clients and keep introducing their friends and partners to Papler Industry.

Packaging & Shipping

1. Q: Where is your company or factory? A: We are located in Xiamen, We have our own factory.2. Q: Can you make design? A: We'll be glad to make mould designs for you, and for free. Complete mould 2D & 3D will supply to clients after order.3. Q: What type of mould you can make? A: We can make all kinds of plastic injection mould, especially rich Experience on household moulds.4. Q: What type of files can you accept? A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.5. Q: What type of steel do you use? A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#6. Q: What kind of material you use for test mould and production? A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC, We have rich experience for manufacturing product with these materials and know how to adjust Parameter to get the perfect product.7. Q: How to send sample? A: The quotation we offer you including The cost of sample delivery 2 times samples by DHL, UPS, EMS,FEDEX or TNT.